May 2021 - John Beaver - Wave Bowl

A few scenes from John Beaver’s virtual demonstration on how he makes his signature wave bowl. For more photos of John’s work, visit http://johnbeaver.net/wood-turning.html.

John Beaver.

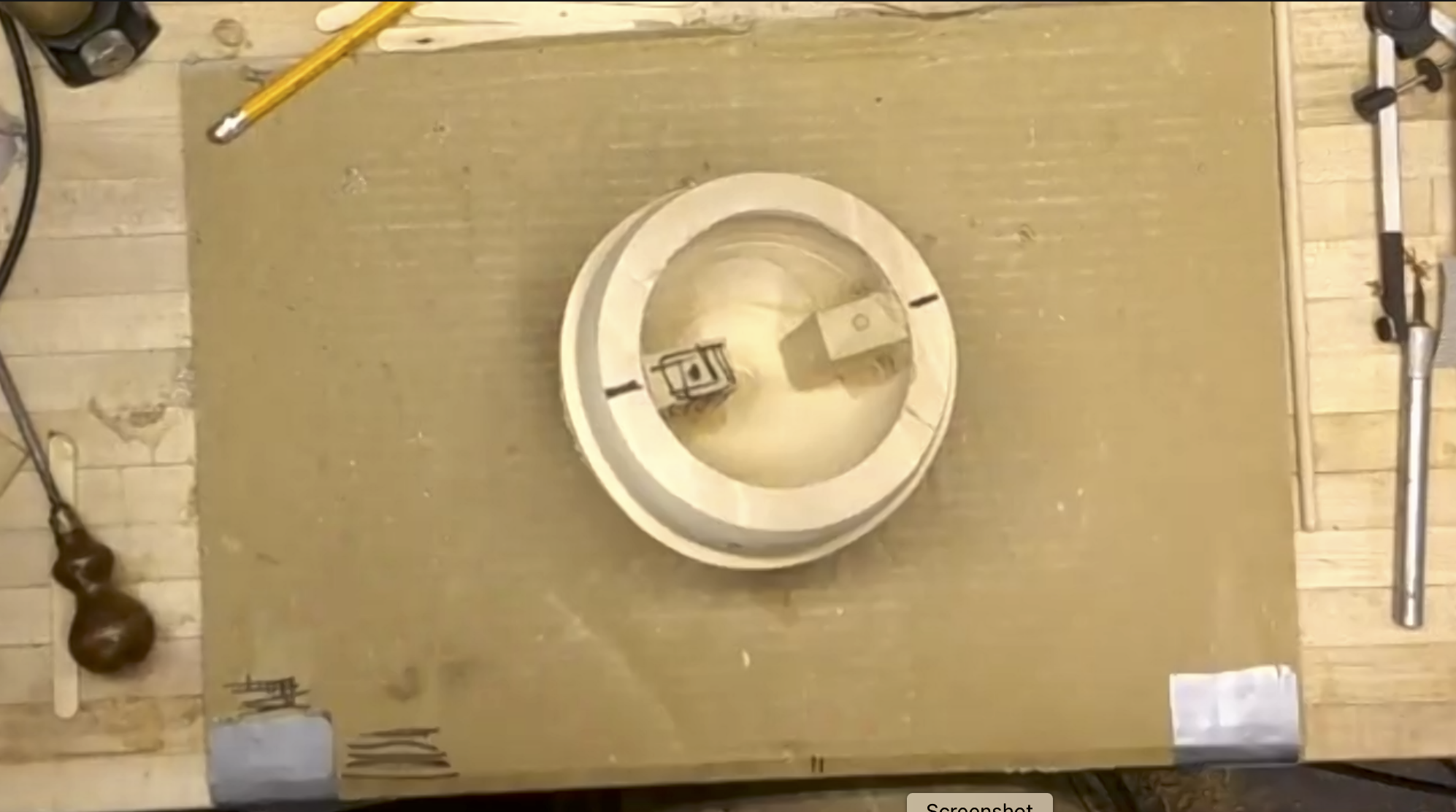

Showing the concept of cuts to be made to the blank.

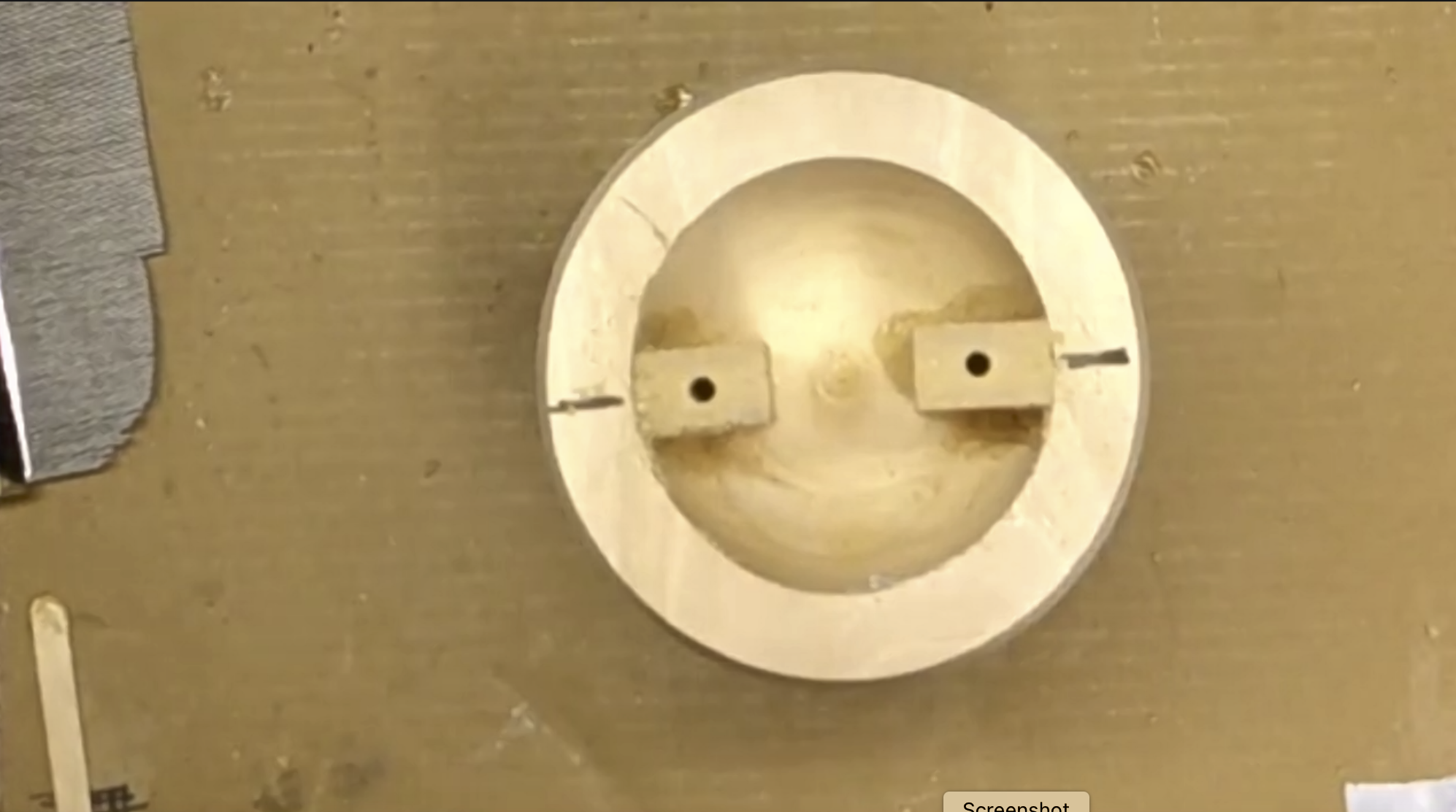

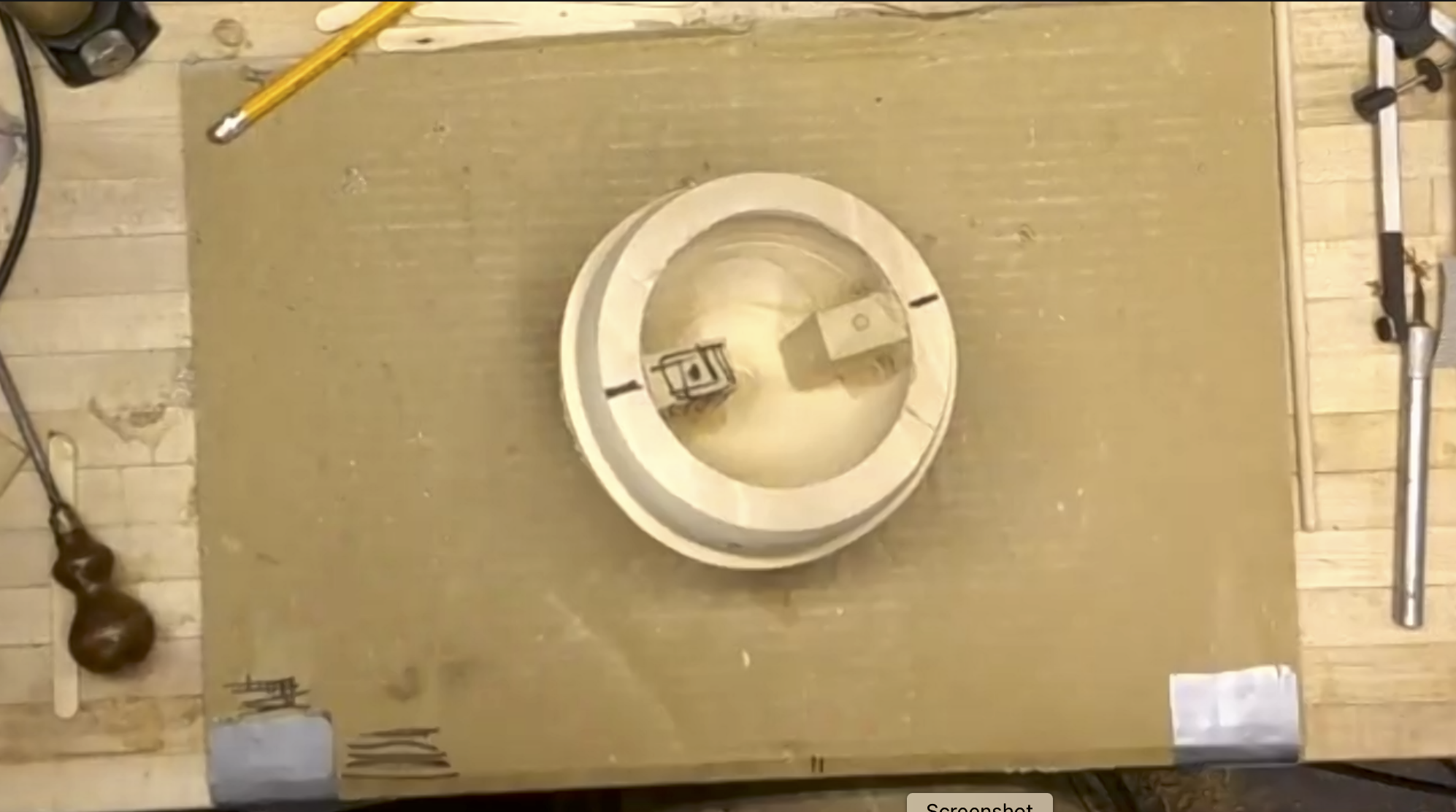

Gluing in supports inside the bowl, that will be drilled for dowels to support the alignment of the pieces as they are reassembled later.

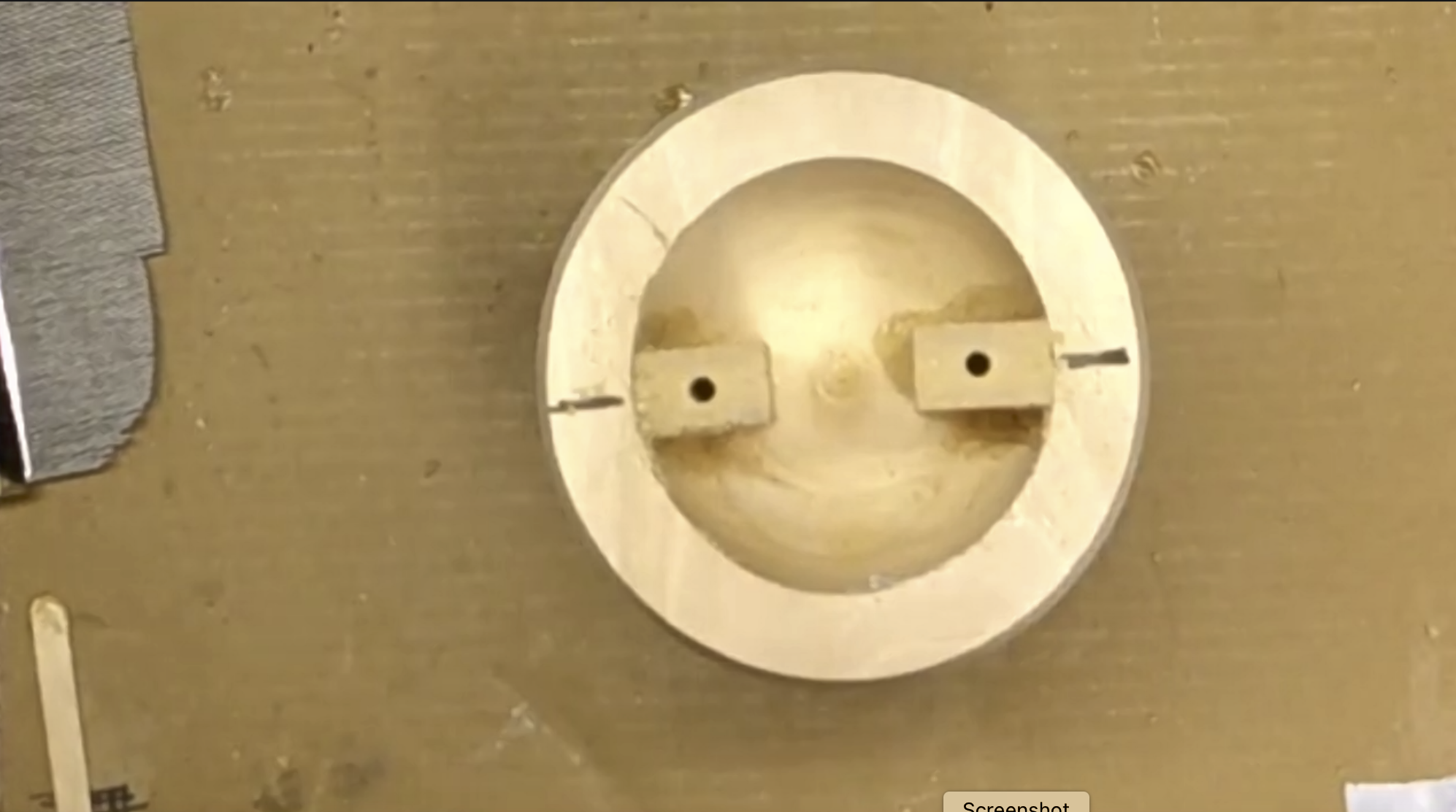

Internal supports drilled for dowels.

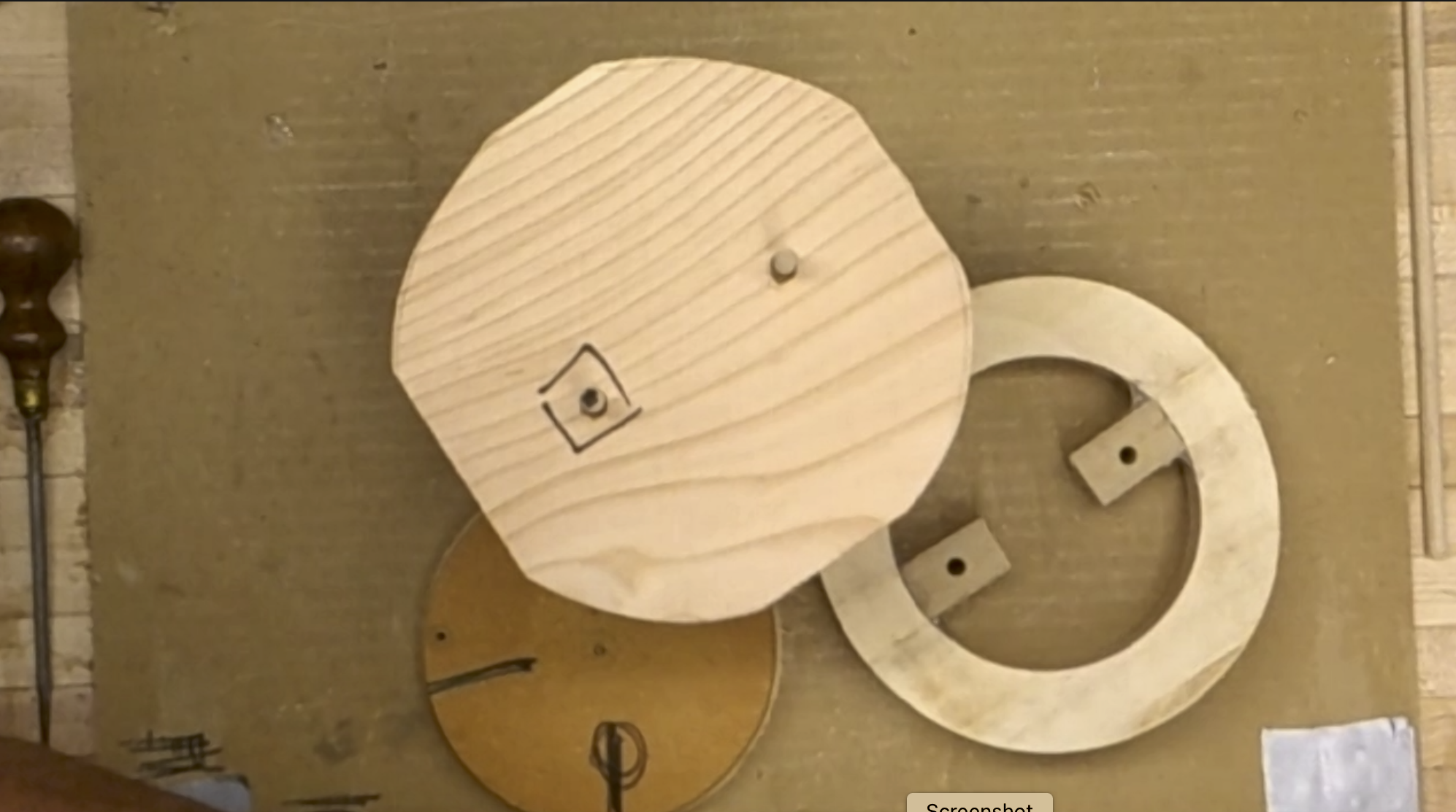

Bandsaw jig used to cut the top off the bowl blank.

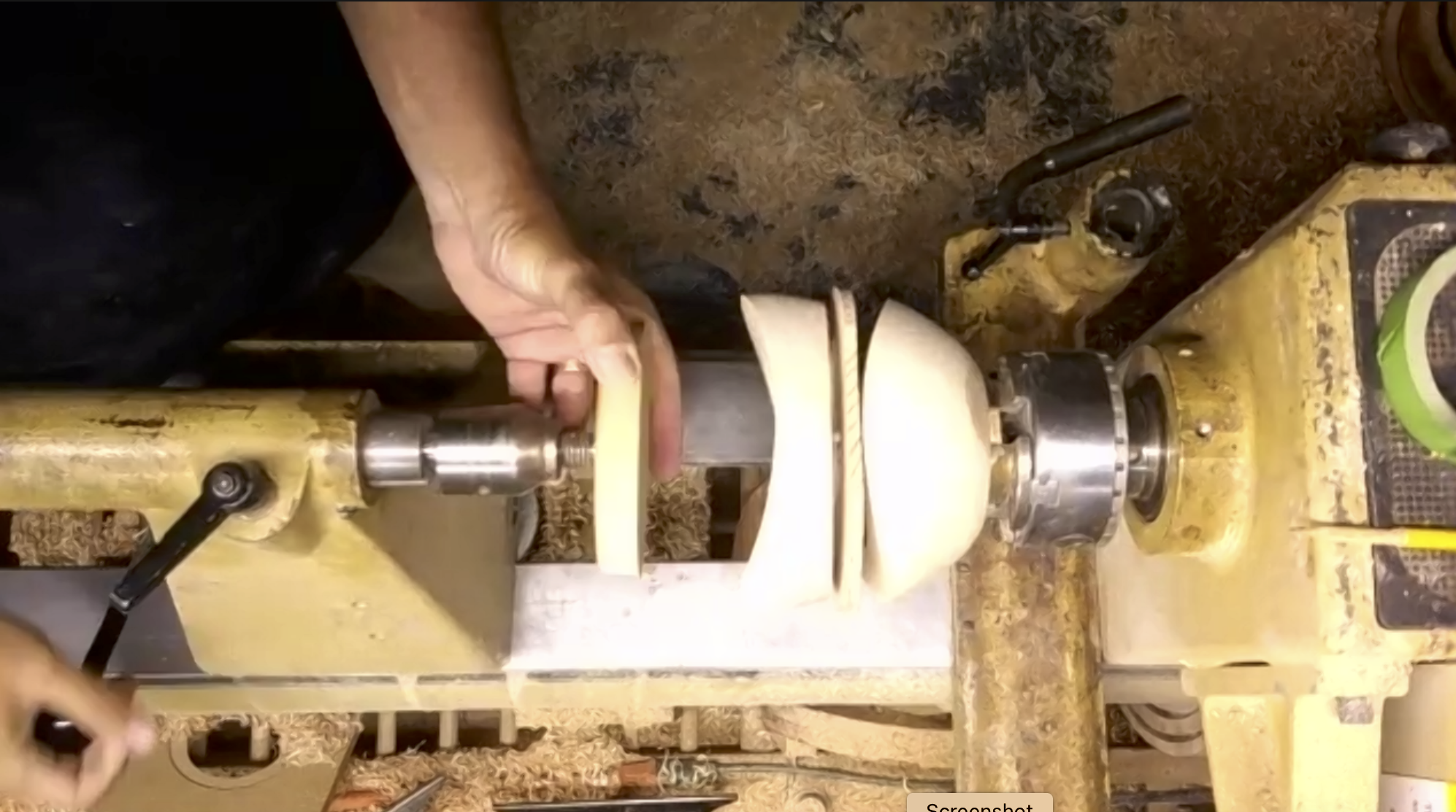

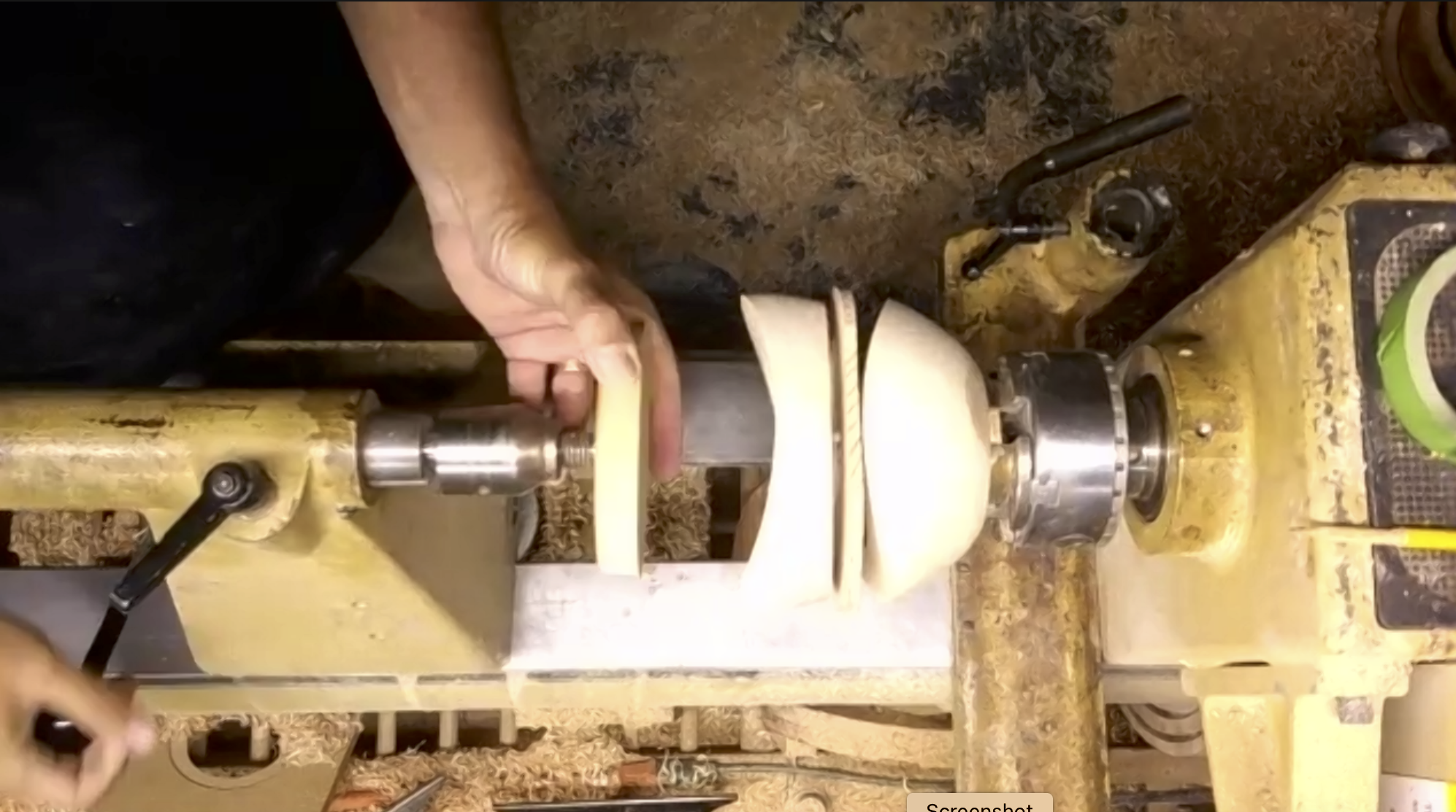

Removing the middle “slice” that will become the wave feature of the final bowl.

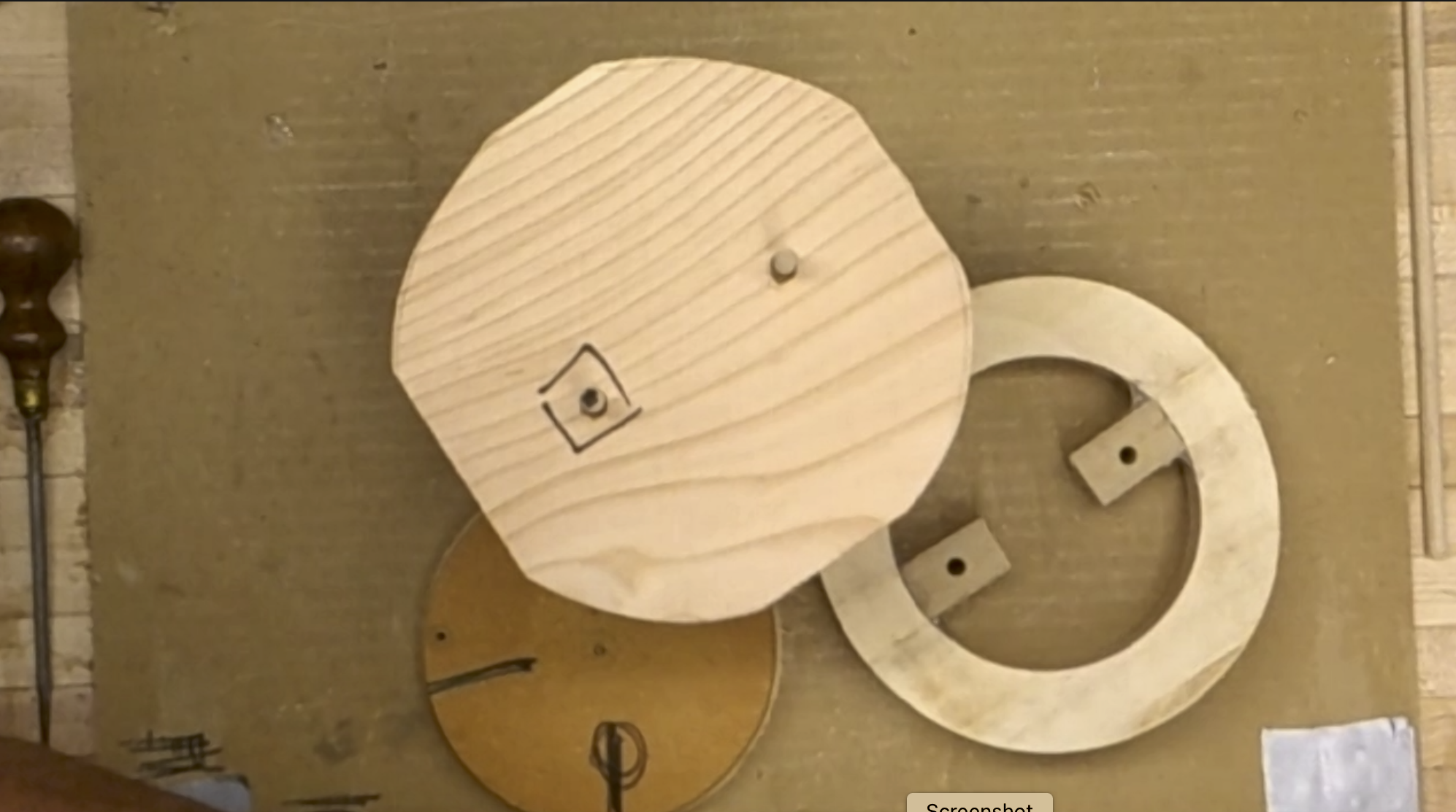

Photo if the middle slice after removing from the blank. Notice the dowel holes for alignment used laster when reassembling the bowl.

Waste wood “wave” that will be steamed and then pressure fit between the top and bottom pieces of the blank.

Fitting the steamed waste wood slice onto the blank.

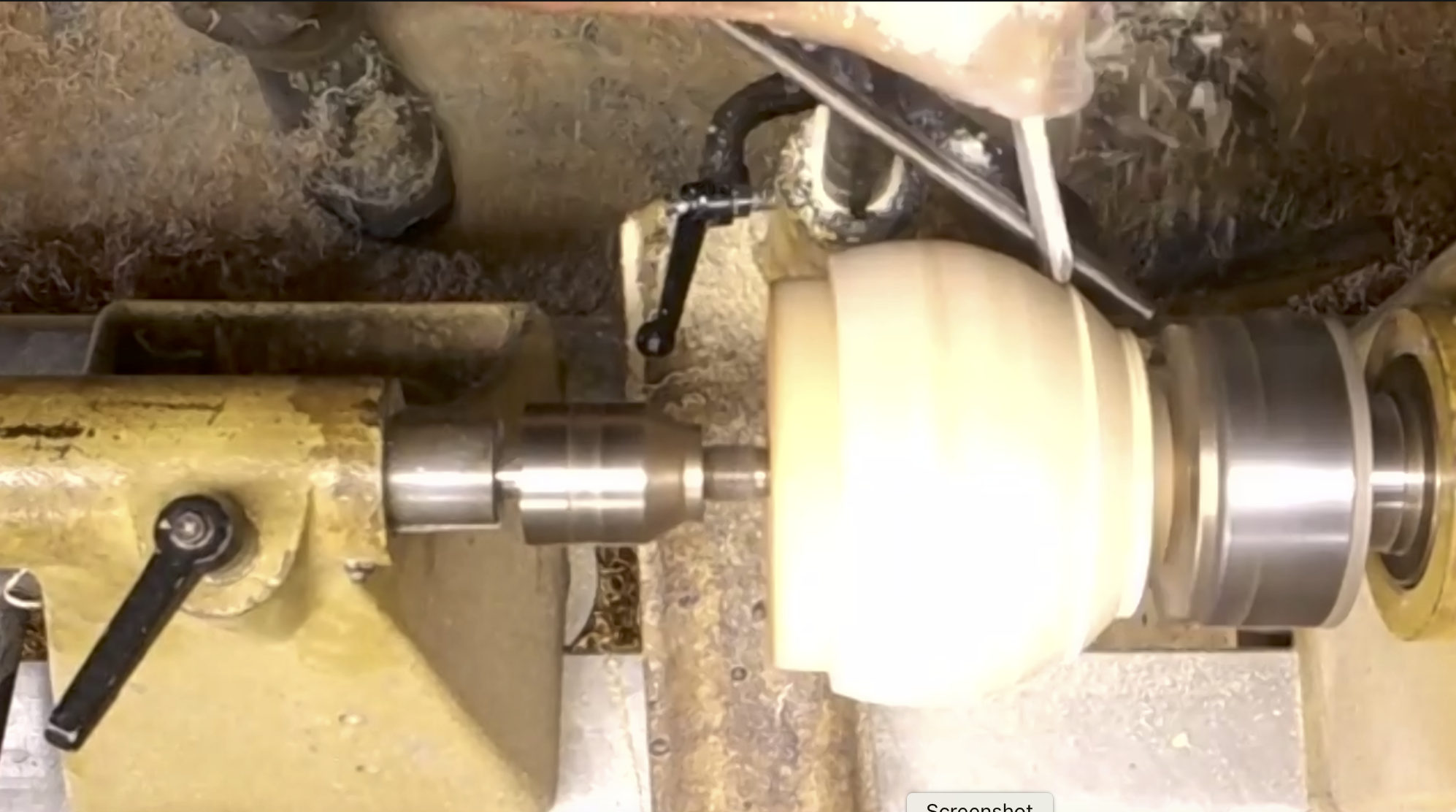

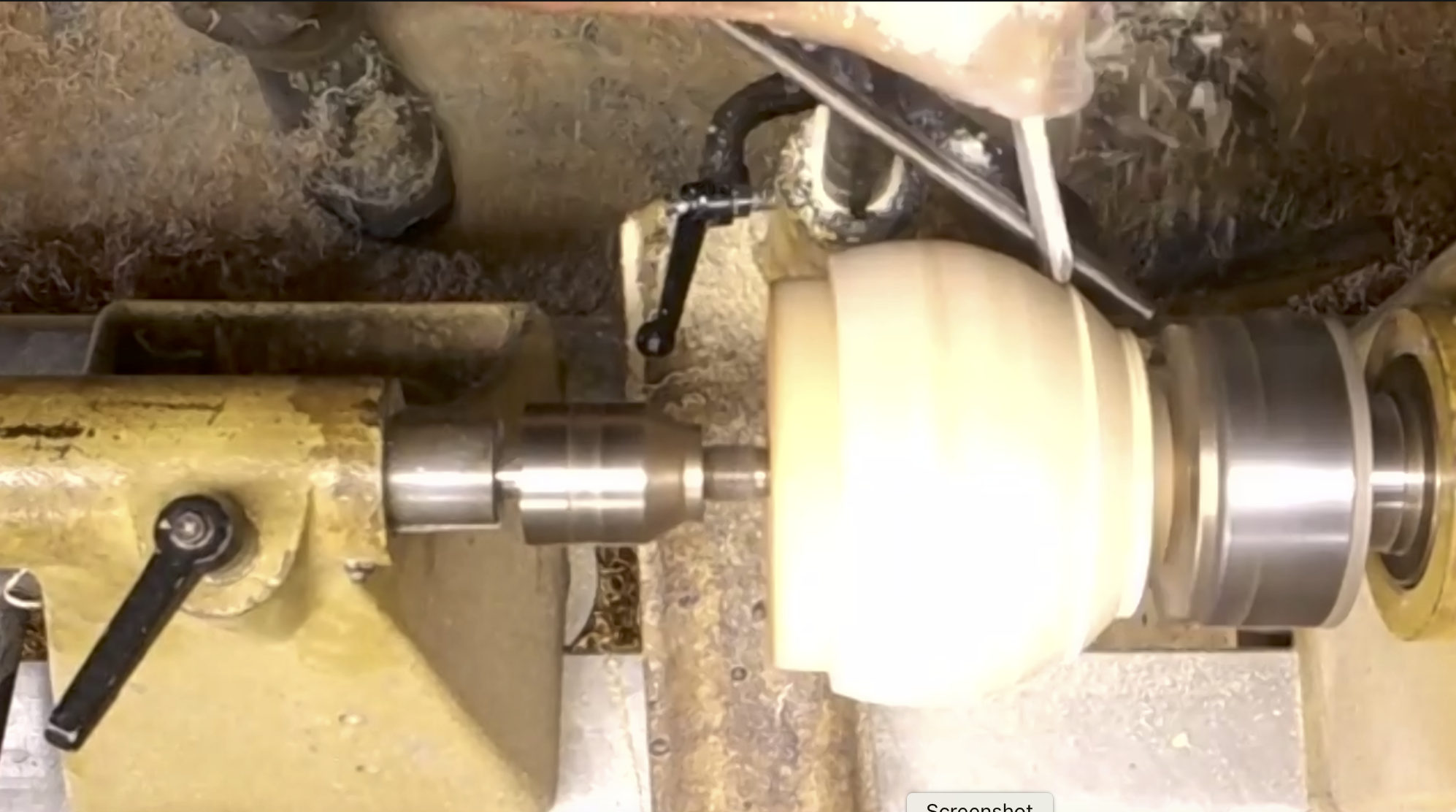

Turning the profile of the bowl blank.

Disassembling the blank to remove the waste wood slice.

Using the supports and dowels to re-insert the original slice (now oversized) between the top and bottom of the bowl blank.

Photo of the reassembled blank.

Examining the wave profile.

Using pliers to remove the glued in supports.